JOINING METHODS

Custom joining technologies for a complete range of connections

For a homogenous, watertight network and a reliable pipe system, several types of connections are available, including plain end, bell spigot with gasket, gasket bell, flange, and electro-fused joints.

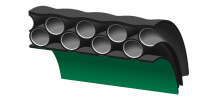

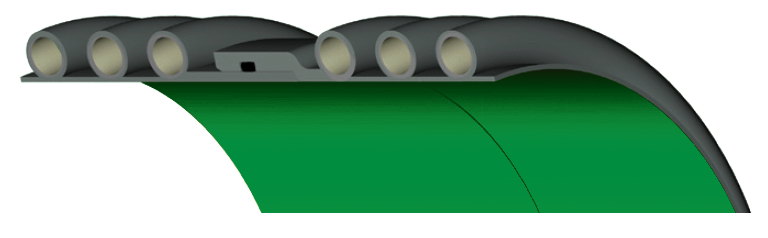

Electrofusion

Our unique electrofusion joining technology ensures watertight and permanent joints, as the whole piping system becomes a seamless unit.

- 125 mm nesting interlocking

- High-strength bell

- Electrofusion wire protected by a plastic film and integrated into the pipe walls prior to shipping

- Waterproofing up to 30 psi (higher value upon request)

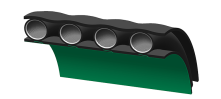

Bell and spigot

- Watertight gasket

- Redundant gaskets to ensure a watertight seal

- Double or single gasket

- 5” (125 mm) spigot insertion depth

- Waterproofing up to 15psi

- Soil-tight gasket

- Cost-efficient joint for when watertightness is not needed

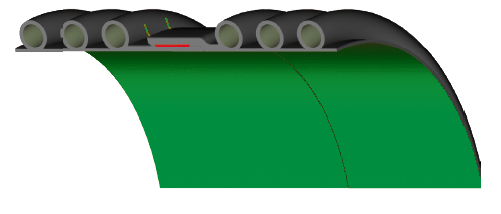

Heat (butt) fusion

The pipes and fittings are jointed with the help of a butt welding machine featuring a heating element. The ends of the pipes and fittings are butt-welded.

- Very high-performance joint

- Often used for pressure applications

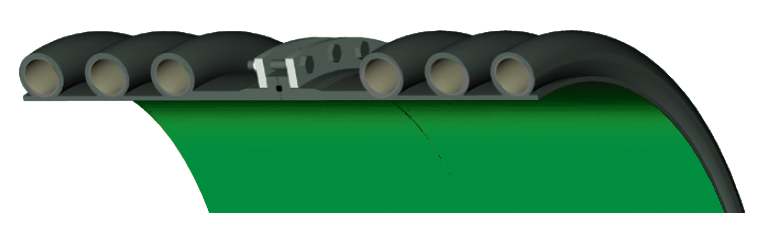

Flange connection

The ends of the pipes and fittings are jointed with the help of a steel flange and a rubber gasket. Depending on the type of pipe, the flange adapters are completely manufactured with the pipe, or the flanges are available as a separate fitting. This kind of jointing method is mostly used for open-sea discharge applications and for tank connections. The greatest advantage of this connection is the facility of disjointing the pipe.